|

Backwoods Series Steam Injection Boilers

|

||

|

Still & Distillery Controllers |

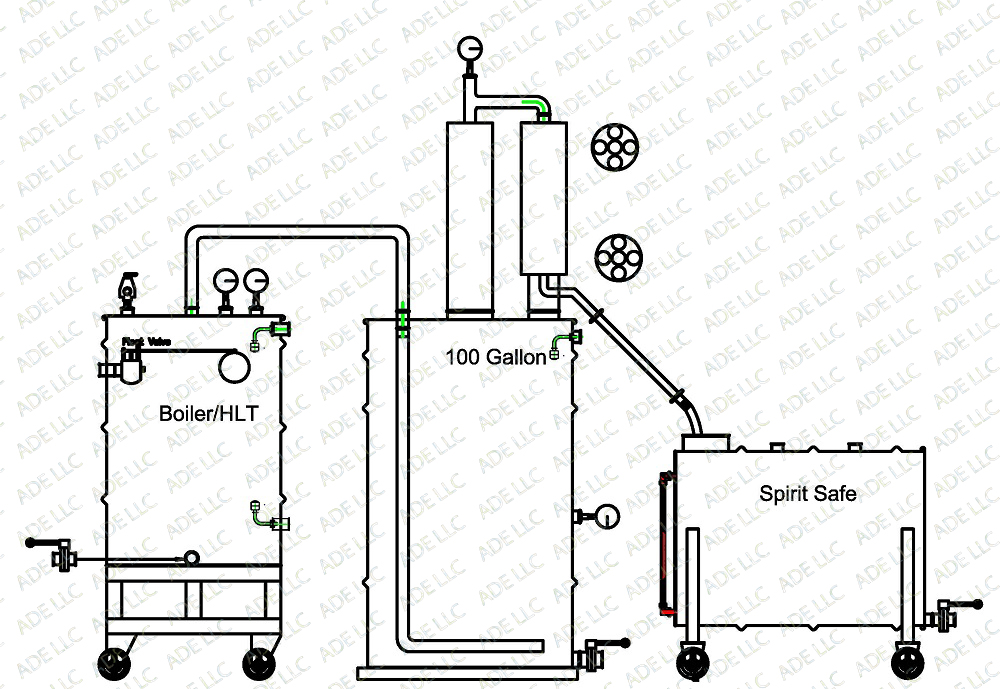

The drawing above shows one of our Backwoods Series 55-100 gallon Steam Injected Mash Tun Stripping Stills with our Backwoods Series Spirit Safes. The vessel to the left is the Steam Injection Boiler, the 100 gallon vessel in the middle is our 100 gallon Combination Mash Tun Stripping Still and the vessel to the left is a portable Spirit Safe. All of our Backwoods Series equipment is built right here at our shop in Missouri, from used stainless steel food grade drums, tanks and kettles. The unit in the picture below to the left is a Steam Injection Boiler. It is filled with water and direct fired by electricity, propane, or natural gas. This is an open system, so the operating pressure is only around 3 PSI. The steam which is around 220° F goes through the pipe coming out of the top of the Steam Injection Boiler and down into the bottom of the Stripping Still. The steam comes out of the pipe in the bottom of the Stripping Still through many small holes that have been drilled in the pipe. These small bubbles of steam heat the mash in the still boiler up to operating temperature fairly quickly compared to some other methods. This system makes noises like a thumper when it is in operation, that is because this system operates very similar to the way that a thumper does. You can also use the steam injection boiler as a hot water source for all of your process needs. You can also use it like an HLT if you want to sparge Barley. Steam injection is an old tried and true method of distilling. The Steam Injected Stripping Still in the photos will produce 30% ABV Low Wines that you can then pour into your Spirit Still for the Spirit Run. If you are going to primarily use corn, then this is the setup for you. You can use the Stripping Still's Boiler fired by the Steam Injection Boiler to cook the corn, then later, once the Corn Mash has fermented (you can ferment in the Stripping Still's boiler if you like) you can add the Quick Attach Stripping Still Head and Gatlin Gun Condenser and do the stripping run. There are some other added benefits to steam injection. Steam produces 10 times more heat than hot water and with steam you don't have to worry about scorching the mash. Since you don't have to worry about scorching the Mash you can do the stripping run on the grain. Doing the stripping run on the grain has several advantages. The first of which, is that you do not lose all of the alcohol that is left in the grain like you do when you separate the liquid from the solids and distill only the liquid. The best advantage of this system is that you separate the liquid from the solids when you do the Stripping Run. To See Our Catalog with all of our different products CLICK HERE |

|

Above is one of our 55 gallon gas fired Backwoods Series Steam Injection Boilers. |

Above is one of our electric 55 gallon Backwoods Series Steam Injection Boilers (right) and one of our 100 gallon Backwoods Series Mash Tuns with agitation and built in cooling coil (left). The Steam Injection Boiler Controller is leaning up against the Mash Tun. |

|