|

|

||

|

Still & Distilling Controllers Bottling & Filtering Equipment

|

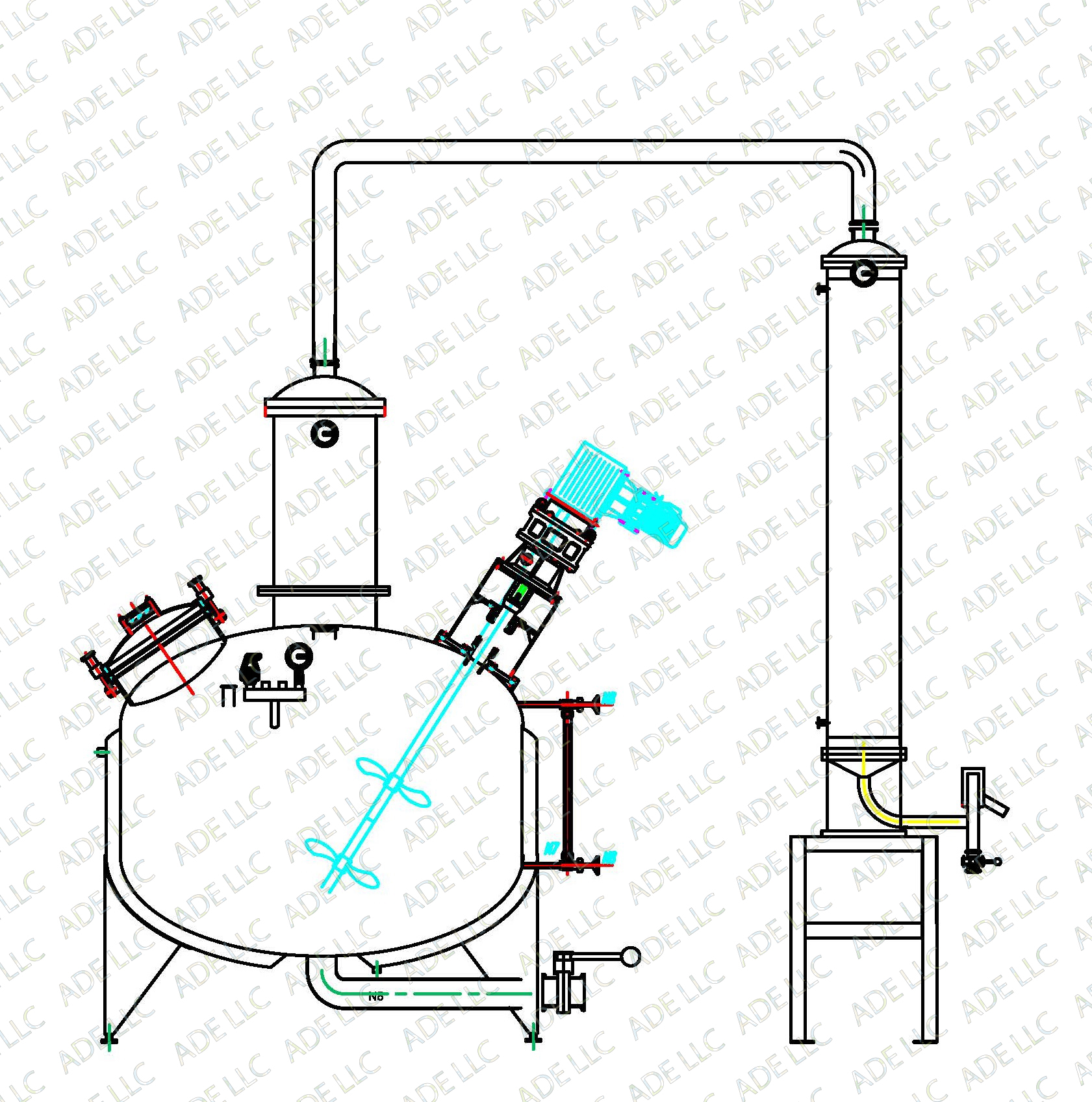

The picture above is of one of our Steam Jacketed Pro Series Stripping Stills. The Stripping Still above has a Variable Speed Agitator, Insulation, CIP, 4" Butterfly Drain Valve, Site Gauge, Pressure Relief and Vacuum Valves, and a large Tube and Shell Condenser that can handle pretty much anything that you can throw at it. These Pro Series Stripping Stills are designed here in the USA and built overseas by a very reputable company that has been building equipment for the US Dairy and Brewing industries for many years. We have several different Pro Series Stripping Stills to choose from in sizes from 50 gallons to 800 gallons. We have Direct Fire Pro Series Stripping Stills, Jacketed Self Contained Pro Series Stripping Stills, Steam Jacketed Pro Series Stripping Stills and Steam Injected Pro Series Stripping Stills.

If you have any questions or if you would like to place an order please call 417-778-6100 or email paul@distillery-equipment.com All major credit cards are accepted. To See Our Catalog with all of our different products CLICK HERE

|

|

|

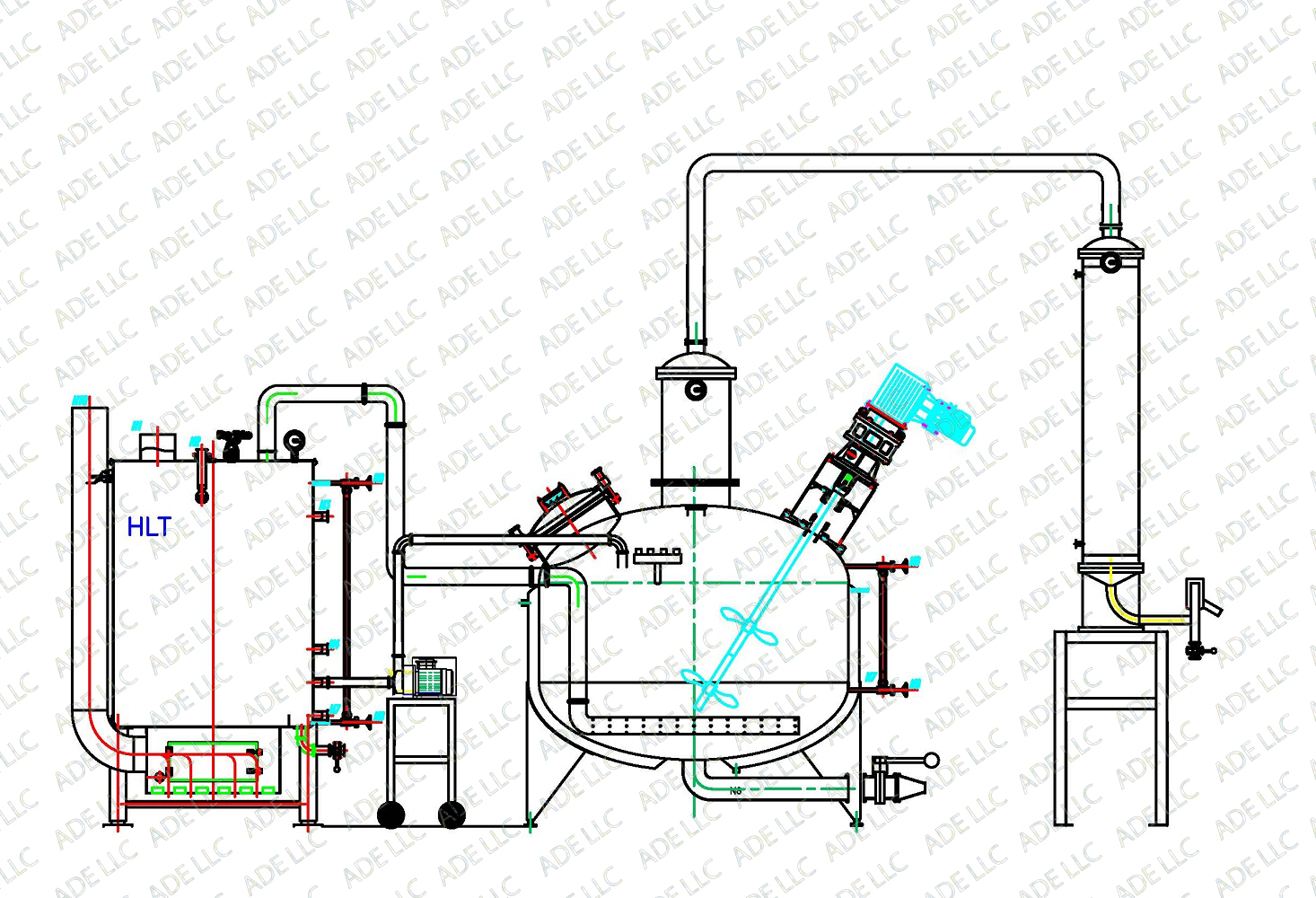

The Design Drawing to the left is of one of our Steam Injected Mash Tun/Stripping Stills. This unit serves as both a Mash Cooker and Stripping Still. The HLT supplies hot water for mashing, CIP and any other process where hot water is needed. The HLT also supplies steam for cooking the mash and for the stripping run as well. If your grain bill primarily consists of corn than this is the set up for you. This system has several advantages over direct fire systems.

Our steam injection boiler fired systems do have disadvantages compared to low pressure steam boilers fired systems. 1. Steam injection is noisy because the vessel being injected with steam makes a banging noise due to the pressure wave created by the hot steam entering the cold mash. As the temperature of the mash increases the thumping will decrease in intensity until it finally stops when the pressure becomes equal. 2 Our steam injection boilers are only about 75% efficient, were as the Rite Low Pressure Steam Boilers that we sell are around 85% efficient. So over the long term, low pressure steam boilers are more cost effective. 3. The largest steam injection HLT that we build has a 200 gallon capacity and produces 320Kbtu The largest still or mash tun that can be fired by it is 300 gallons. 4. Though we have Steam Injection HLTs that are operating in distilleries all over the US, a low pressure steam boiler is easier to get past the inspectors in most instances. However, all of our customers who purchased our Steam injection HLTs got those units through the inspection process.

|

|